More accurate in soils with high bulk electrical conductivity

Overview

The CS650 is a multiparameter smart sensor that uses innovative techniques to monitor soil volumetric water content, bulk electrical conductivity, and temperature. It outputs an SDI-12 signal that many of our data loggers can measure.

Note: The cable termination options for this sensor are not suitable for use with an ET107 station. For this type of station, use the CS650-LC sensor instead, which has a suitable cable connector.

Read MoreBenefits and Features

- More accurate water content measurements in soils with bulk EC up to 3 dS m-1 without performing a soil-specific calibration

- Larger sample volume reduces error

- Measurement corrected for effects of soil texture and electrical conductivity

- Estimates soil-water content for a wide range of mineral soils

- Versatile sensor—measures dielectric permittivity, bulk electrical conductivity (EC), and soil temperature

Images

Similar Products

Detailed Description

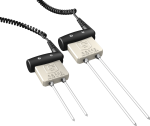

The CS650 consists of two 30-cm-long stainless steel rods connected to a printed circuit board. The circuit board is encapsulated in epoxy and a shielded cable is attached to the circuit board for data logger connection.

The CS650 measures propagation time, signal attenuation, and temperature. Dielectric permittivity, volumetric water content, and bulk electrical conductivity are then derived from these raw values.

Measured signal attenuation is used to correct for the loss effect on reflection detection and thus propagation time measurement. This loss-effect correction allows accurate water content measurements in soils with bulk EC ≤3 dS m-1 without performing a soil specific calibration.

Soil bulk electrical conductivity is also calculated from the attenuation measurement. A thermistor in thermal contact with a probe rod near the epoxy surface measures temperature. Horizontal installation of the sensor provides accurate soil temperature measurement at the same depth as the water content. Temperature measurement in other orientations will be that of the region near the rod entrance into the epoxy body.

Specifications

| Measurements Made | Soil electrical conductivity (EC), relative dielectric permittivity, volumetric water content (VWC), soil temperature |

| Required Equipment | Measurement system |

| Soil Suitability | Long rods with large sensing volume (> 6 L) are suitable for soils with low to moderate electrical conductivity. |

| Rods | Not replaceable |

| Sensors | Not interchangeable |

| Sensing Volume | 7800 cm3 (~7.5 cm radius around each probe rod and 4.5 cm beyond the end of the rods) |

| Electromagnetic |

CE compliant Meets EN61326 requirements for protection against electrostatic discharge and surge. |

| Operating Temperature Range | -50° to +70°C |

| Sensor Output | SDI-12; serial RS-232 |

| Warm-up Time | 3 s |

| Measurement Time | 3 ms to measure; 600 ms to complete SDI-12 command |

| Power Supply Requirements | 6 to 18 Vdc (Must be able to supply 45 mA @ 12 Vdc.) |

| Maximum Cable Length | 610 m (2000 ft) combined length for up to 25 sensors connected to the same data logger control port |

| Rod Spacing | 32 mm (1.3 in.) |

| Ingress Protection Rating | IP68 |

| Rod Diameter | 3.2 mm (0.13 in.) |

| Rod Length | 300 mm (11.8 in.) |

| Probe Head Dimensions | 85 x 63 x 18 mm (3.3 x 2.5 x 0.7 in.) |

| Cable Weight | 35 g per m (0.38 oz per ft) |

| Probe Weight | 280 g (9.9 oz) without cable |

Current Drain |

|

| Active (3 ms) |

|

| Quiescent | 135 µA typical (@ 12 Vdc) |

Electrical Conductivity |

|

| Range for Solution EC | 0 to 3 dS/m |

| Range for Bulk EC | 0 to 3 dS/m |

| Accuracy | ±(5% of reading + 0.05 dS/m) |

| Precision | 0.5% of BEC |

Relative Dielectric Permittivity |

|

| Range | 1 to 81 |

| Accuracy |

|

| Precision | < 0.02 |

Volumetric Water Content |

|

| Range | 0 to 100% (with M4 command) |

| Water Content Accuracy |

|

| Precision | < 0.05% |

Soil Temperature |

|

| Range | -50° to +70°C |

| Resolution | 0.001°C |

| Accuracy |

|

| Precision | ±0.02°C |

Compatibility

Note: The following shows notable compatibility information. It is not a comprehensive list of all compatible or incompatible products.

Data Loggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

RF Considerations

External RF Sources

External RF sources can affect the probe’s operation. Therefore, the probe should be located away from significant sources of RF such as ac power lines and motors.

Interprobe Interference

Multiple CS650 sensors can be installed within 4 inches of each other when using the standard data logger SDI-12 “M” command. The SDI-12 “M” command allows only one probe to be enabled at a time.

Installation Tool

The CS650G makes inserting soil-water sensors easier in dense or rocky soils. This tool can be hammered into the soil with force that might damage the sensor if the CS650G were not used. It makes pilot holes into which the rods of the sensors can then be inserted.

Downloads

CS650 / CS655 Firmware v.2 (429 KB) 02-12-2015

Current CS650 and CS655 firmware.

Note: The Device Configuration Utility and A200 Sensor-to-PC Interface are required to upload the included firmware to the sensor.

Frequently Asked Questions

Number of FAQs related to CS650: 50

Expand AllCollapse All

-

The electrical conductivity (EC) of sea water is approximately 48 dS/m. The CS650 can measure permittivity in water with EC between 0 and 3 dS/m. EC readings become extremely unstable at conductivities higher than 3 dS/m and are reported as NAN or 9999999. Because EC is part of the permittivity equation, an EC reading of NAN leads to a permittivity reading of NAN as well. Thus, the CS650 cannot provide good readings in sea water.

With regard to sea ice, the electrical conductivity drops significantly when sea water freezes and the permittivity changes from approximately 88 down to approximately 4, as the water changes from a liquid to a solid state. With both EC and permittivity falling to levels that are within the CS650 measurement range, the sensor is expected to give valid readings in sea ice. The sensor is rugged and can withstand the cold temperatures. However, as the ice melts, there will be a point at which the electrical conductivity becomes too high to acquire a valid reading for either permittivity or electrical conductivity.

-

Campbell Scientific strongly discourages shortening the sensor’s rods. The electronics in the sensor head have been optimized to work with the 30 cm long rods. Shortening these rods will change the period average. Consequently, the equations in the firmware will become invalid and give inaccurate readings.

-

Mine tailings are highly corrosive and have high electrical conductivity. Some customers have successfully used water content reflectometers, such as the CS650 or the CS655, to measure water content in mine tailings by coating the sensor rods with heat-shrink tubing. This affects the sensor output, and a soil-specific calibration must be performed. Care must be taken during installation to avoid damaging the heat-shrink tubing and exposing the sensor’s rods. In addition, covering the sensor’s rods invalidates the bulk electrical conductivity reading. Unless the temperature reading provided by the CS650 or the CS655 is necessary, a better option may be to use a CS616 with coated rods.

-

The permittivity of saturated sediments in a stream bed is expected to read somewhere between 25 and 42, while the permittivity of water is close to 80. A CS650 or CS655 installed in saturated sediments could be used to monitor sediment erosion. If the permittivity continuously increases beyond the initial saturated reading, this is an indication that sediment around the sensor rods has eroded and been replaced with water. A calibration could be performed that relates permittivity to the depth of the rods still in the sediment.

-

Period average and electrical conductivity readings were taken with several sensors in solutions of varying permittivity and varying electrical conductivity at constant temperature. Coefficients were determined for a best fit of the data. The equation is of the form

Ka(σ,τ) = C0*σ3*τ2 + C1*σ2*τ2 + C2*σ*τ2 + C3*τ2 + C4*σ3*τ + C5*σ2*τ + C6*σ*τ + C7*τ + C8*σ3 + C9*σ2 + C10*σ + C11

where Ka is apparent dielectric permittivity, σ is bulk electrical conductivity (dS/m), τ is period average (μS), and C1 to C11 are constants.

-

Yes. There is surge protection built into the sensor electronics. The sensor survives a surge of 2 kV at 42 ohm line-to-ground on digital I/O and 2 kV at 12 ohm line-to-ground on power. It also survives a surge of 2 kV at 2 ohm line-to-ground on the rods.

If additional surge protection is required, consider using the SVP100 Surge Voltage Protector DIN Rail with Mounting Hardware.

-

No. It is not possible to disable the logical tests in the firmware. If soil conditions cause frequent NAN values, it may be possible to perform a soil-specific calibration that will provide good results.

If permittivity is reported but the volumetric water content value is NAN, Campbell Scientific recommends a soil-specific calibration that converts permittivity to water content. This will take advantage of the bulk electrical conductivity correction that occurs in the firmware.

If both permittivity and volumetric water content have NAN values, it may be possible to perform a calibration that converts period average directly to volumetric water content.

For details on performing a soil-specific calibration, refer to “The Water Content Reflectometer Method for Measuring Volumetric Water Content” section in the CS650/CS655 manual. After a soil-specific equation is determined, it may be programmed into the data logger program or used in a spreadsheet to calculate the soil water content.

-

In soil that is sandy, sandy loam, or loamy sand with low electrical conductivity, the CS650 is a suitable option because it has slightly better accuracy specifications than the CS655 and a larger measurement volume.

-

Probably not. The principle that makes these sensors work is that liquid water has a dielectric permittivity of close to 80, while soil solid particles have a dielectric permittivity of approximately 3 to 6. Because the permittivity of water is over an order of magnitude higher than that of soil solids, water content has a significant impact on the overall bulk dielectric permittivity of the soil. When the soil becomes very dry, that impact is minimized, and it becomes difficult for the sensor to detect small amounts of water. In air dry soil, there is residual water that does not respond to an electric field in the same way as it does when there is enough water to flow among soil pores. Residual water content can range from approximately 0.03 in coarse soils to approximately 0.25 in clay. In the natural environment, water contents below 0.05 indicate that the soil is as dry as it is likely to get. Very small changes in water content will likely cause a change in the sensor period average and permittivity readings, but, to interpret those changes, a very careful calibration using temperature compensation would need to be performed.

-

Because the reported volumetric water content reading is an average taken along the entire length of the rods, the sensor should be fully inserted into the soil. Otherwise, the reading will be the average of both the air and the soil, which will lead to an underestimation of water content. If the sensor rods are too long to go all the way into the soil, Campbell Scientific recommends inserting the rods at an angle until they are fully covered by soil.

Case Studies

Agrivoltaics or dual-use solar is a system combining an agricultural crop (viticulture, arboriculture, field crops,......read more

Articles and Press Releases

Newsletter Articles

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences