Designed for flux and other turbulence research projects

Overview

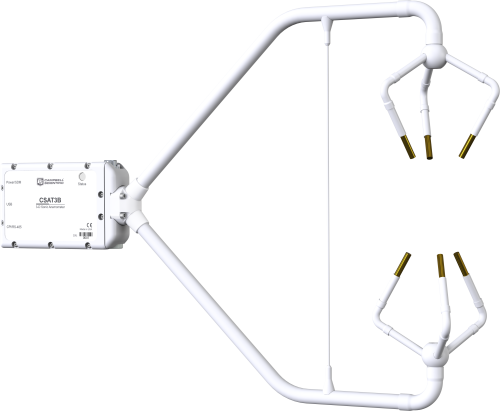

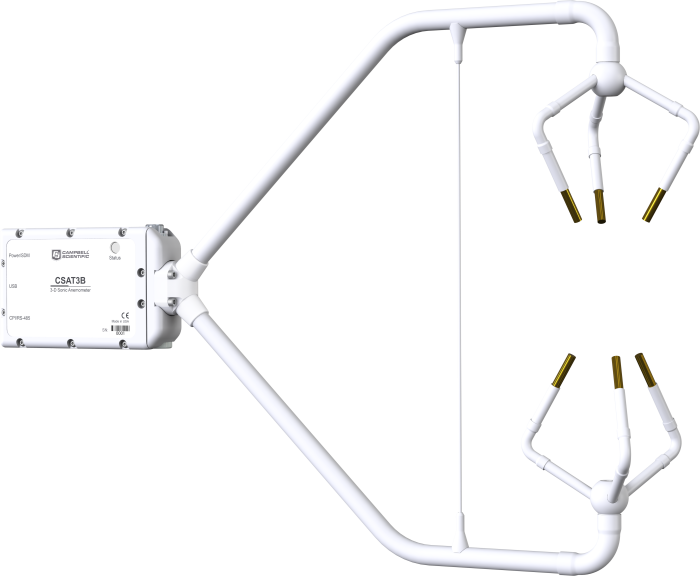

Campbell Scientific’s CSAT3B 3-D Sonic Anemometer is an update and replacement to the original CSAT3, and remains the 3-D sonic anemometer of choice for eddy-covariance measurements. It has an aerodynamic design, a 10 cm vertical measurement path, operates in a pulsed acoustic mode, and withstands exposure to harsh weather conditions. Three orthogonal wind components (ux, uy, uz) and the sonic temperature (Ts) are measured and output at a maximum rate of 100 Hz.

The most conspicuous innovation of the new design is the elimination of the electronics box. Instead, the electronics are packaged inside the mounting block of the CSAT3B head. This design feature makes installation easier and offers greater flexibility in instrument placement.

Measurements can be triggered from three sources:

- Data logger SDM command

- Data logger CPI command

- CSAT3B internal clock

The SDM and CPI protocols both support mechanisms for synchronizing multiple CSAT3Bs.

Benefits and Features

- New conformal coating helps protect sonic transducers in corrosive environments

- Integrated electronics that provide easy mounting of a single piece of hardware

- Integrated inclinometer

- High-precision measurements ideal for turbulence and eddy-covariance studies

- An improved design with a thin, aerodynamic support strut close to the ends of the sensor arms, creating greater rigidity and improved accuracy of sonic temperature

- Data logger sampling supported for any frequency between 1 and 100 Hz

- New CPI communications for more robust, higher bandwidth measurements

- Multiple communication options including SDM, CPI, USB, and RS-485

- Internal temperature and humidity measurements with easily replaced desiccant

- Version 5 algorithm for calculating data outputs; combines the signal sensitivity of version 3 with the rain performance of version 4

- Includes options to filter high frequencies for applications requiring analysis of non-aliased spectra

Images

Specifications

| Sensor | 3-dimensional sonic anemometer |

| Measurement Description | Highest-quality wind speed and direction |

| Operating Temperature Range | -40 to +50°C (equivalent to 305 to 368 m s-1 in speed of sound) |

| Outputs | ux, uy, uz, Ts (ux, uy, uz are wind components referenced to the anemometer axes; Ts is sonic temperature in degrees Celsius.) |

| Signal Type/Output | SDM, CPI, USB, RS-485 |

| Speed of Sound | Determined from three acoustic paths. (Corrected for crosswind effects.) |

| Wind Direction Range | 2.5 to 357.5° in CSAT3B coordinate system (0 to 360° customized) |

| Range | ± 65 m s–1 (full-scale wind) |

| Filter Bandwidths | 5, 10, or 25 Hz |

| Measurement Path Length | 10.0 cm (3.9 in.) vertical; 5.8 cm (2.3 in.) horizontal |

| Transducer Angle from Horizontal | 60 degrees |

| Ingress Protection | IP67 |

| Transducer Diameter | 0.64 cm (0.25 in.) |

| Transducer Mounting Arm Diameter | 0.84 cm (0.33 in.) |

| Support Arm Diameter | 1.59 cm (0.63 in.) |

| Anemometer Head Weight | 1.45 kg (3.2 lb) |

| Anemometer Dimensions | 60.64 x 12.2 x 43.0 cm (23.87 x 4.8 x 16.9 in.) |

Wind Accuracy |

|

| -NOTE- |

Accuracy specifications assume the following:

|

| Maximum Offset Error | < ±8.0 cm s-1 (ux, uy), < ±4.0 cm s-1 (uz) |

| Maximum Gain Error |

|

Measurement Resolution |

|

| ux, uy | 1 mm s-1 rms |

| uz | 0.5 mm s-1 rms |

| Ts | 0.002°C RMS (at 25°C) |

| Wind Direction | < 0.058° (ux = uy ≤ 1 m s-1) |

Measurement Rates |

|

| Data Logger Triggered | 1 to 100 Hz |

| Unprompted Output (to PC) | 10, 20, 50, or 100 Hz |

| Internal Self-Trigger Rate | 100 Hz |

Measurement Delay |

|

| Data Logger Triggered (no filter) | 1 trigger period (1 scan interval) |

| Unprompted Output (no filter) | 10 ms |

| Filtered Output (data-logger-prompted or unprompted to PC) |

|

Internal Monitor Measurements |

|

| Update Rate | 2 Hz |

| Inclinometer Accuracy | ±1° |

| Relative Humidity Accuracy |

|

| Board Temperature Accuracy | ±2°C |

SDM |

|

| -NOTE- | Used for data-logger-based data acquisition. |

| Bit Period | 10 µs to 1 ms |

| Cable Length |

|

| Address Range | 1 to 14 |

| Bus Clocks per Sample | ~200 |

CPI |

|

| -NOTE- | Used for data-logger-based data acquisition. |

| Baud Rate | 50 kbps to 1 Mbps |

| Cable Length |

|

| Address Range | 1 to 120 |

| Bus Clocks per Sample | ~300 |

RS-485 |

|

| -NOTE- | Used for configuration or PC-based data acquisition. |

| Baud Rate | 9.6 kbps to 115.2 kbps |

| Cable Length |

|

| Bus Clocks per Sample | ~500 (ASCII formatted) |

USB |

|

| -NOTE- | Used for configuration or PC-based data acquisition. |

| Connection Speed | USB 2.0 full speed 12 Mbps |

| Cable Length | 5 m (16.4 ft) maximum |

Power Requirements |

|

| Voltage Supply | 9.5 to 32 Vdc |

| Current at 10 Hz Measurement Rate |

|

| Current at 100 Hz Measurement Rate |

|

Compatibility

Note: The following shows notable compatibility information. It is not a comprehensive list of all compatible or incompatible products.

Data Loggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

The CSAT3B works with standard USB ports on most computers. However, for consistent communications—especially when using multiple USB devices or lower-powered ports (such as those on laptops or hubs without power)—we recommend using a powered USB hub for optimal performance.

Documents

Technical Papers

Miscellaneous

Videos & Tutorials

Downloads

CSAT3B Example Programs v.1 (4 kB) 20-10-2020

Three example programs.

Simple SDM Program: SDM communications are used to collect data from a single CSAT3B.

Simple CPI Program: CPI communications are used to collect data from a single CSAT3B.

Advanced CPI Program: A single CSAT3B is properly configured and CPI communications are used to collect the data.

CPI Calculator v.1.0 (2.49 MB) 06-07-2016

The CPI Calculator is a downloadable Microsoft Excel spreadsheet used to estimate the usage and capacity of a CPI network. The calculator provides an overview on CPI devices including the CDM-A108, CDM-A116, CDM-VW300, CDM-VW305, and the CSAT3B. The calculator can also estimate the measurement speed of the CDM-A108 and CDM-A116 based on the number of channels and measurement parameters.

The CPI Calculator is an estimation tool and will help you better understand and design CPI networks by considering the following:

- What is the capability of each CDM or CPI device

- What is the CPI network capacity

- How much of the CPI capacity are the CDMs or CPI devices using

Frequently Asked Questions

Number of FAQs related to CSAT3B: 16

Expand AllCollapse All

-

Ultrasonic anemometers are unable to make measurements if the sonic path is blocked. The path may become blocked by water that puddles on the lower transducer face or droplets that hang from the upper transducers. Sonic wicks, which come with all sonics, can be placed on the transducers to wick away moisture from the faces of the transducers. Ensure that these wicks are removed during cold conditions to prevent ice from building up around them.

-

Campbell Scientific does not offer any mounting booms or hardware that enable easy and frequent positioning of the sonic anemometer sensor head. This type of hardware must be provided by the user.

-

Yes. If the matching layer is damaged or missing, return the sonic anemometer to the factory for repair. Follow the steps listed on our Repair and Calibration page to request a return material authorization (RMA) number.

-

The CSAT3A or CSAT3B is calibrated over the temperature range of -30° to +50°C. The sonic anemometer operating temperature range can be shifted by 10 degrees to cover the range of -40° to +40°C. For low-temperature applications, it may be more appropriate to consider a heated version of our sonic anemometers.

The instrument will continue to operate outside the calibrated temperature range until the signal becomes too weak; however, the proper calibration will not be applied to the measurements because the calibration file only spans the specified temperature range.

-

The sonic anemometer offset specification is ±8 cm/s. Therefore, it cannot be used in an application where the expected wind speed is in the range of ±5 cm/s.

-

The CSAT3A, CSAT3AH, CSAT3B, and CSAT3BH are calibrated over temperature for the effects of transducer delays on the wind speed, and to a lesser extent, for the speed of sound measurements.

There is no NIST-traceable standard for ultrasonic anemometers.

-

Yes. The CSAT3B and CSAT3BH measurement frequency can be changed by the user. The user can either choose a prompted or unprompted output rate. The prompted output rate is based on the scan interval of the data logger, which must be an integer. Therefore, the measurement frequencies supported would be 1, 2, 4, 5, 8, 10, 20, 25, 40, 50, and 100 Hz. The unprompted output rate allowed is 10, 20, 50, and 100 Hz.

-

The CSAT3A, CSAT3AH, CSAT3B, and CSAT3BH—like other sonic anemometers—measure wind speed along the sonic path using ultrasonic signals. If the salt spray blocks the sonic path, the sonic anemometer will not be able to make measurements. The same is true if a thick layer of salt is deposited on the transducer faces.

-

No. The sonic anemometer does not report time with the wind measurements. A time stamp will be assigned to the wind data by the data-acquisition system—either a data logger or a PC.

Case Studies

Overview In the heart of the UAE’s Empty Quarter desert—one of the harshest and least hospitable......read more

Articles and Press Releases

Newsletter Articles

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences